by Helen Fletcher | Oct 25, 2024 | Case Study

Since 2006, we’ve been working with our client in North Yorkshire to support their production of high-quality micronised cereals and pulses for the animal feed and brewing industries. Recently, we have been completing key projects at their mill to enhance their...

by Helen Fletcher | Sep 20, 2024 | Case Study

What was the issue? We were recently contacted by an existing client based in Carlisle, who specialises in the production of high-quality ruminant feeds. The client asked us if it was possible to automate the blending process in their animal feed mill, to improve...

by Helen Fletcher | Aug 20, 2024 | Case Study

What was the issue? Our Northern Ireland based client needed an upgrade to the conveyors in their animal feed mill which specialises in the production of ruminant feed. The existing set up had one slightly inclined conveyor under the two existing weighers that fed a...

by Helen Fletcher | Jul 23, 2024 | Case Study

WHAT WAS THE ISSUE? Our client, a manufacturer and supplier of ruminant compound feeds and blends based near Carlisle, had added new silos and weighers to increase the size of their mill and production capacity around six years ago. However, they were still using one...

by Helen Fletcher | Jun 11, 2024 | Case Study

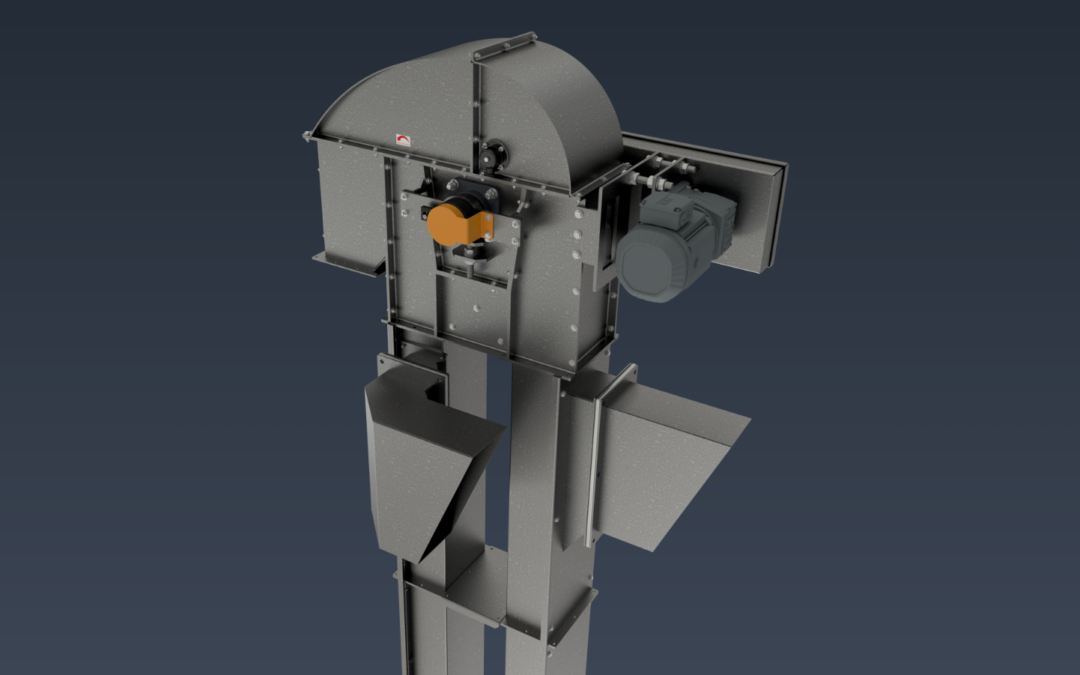

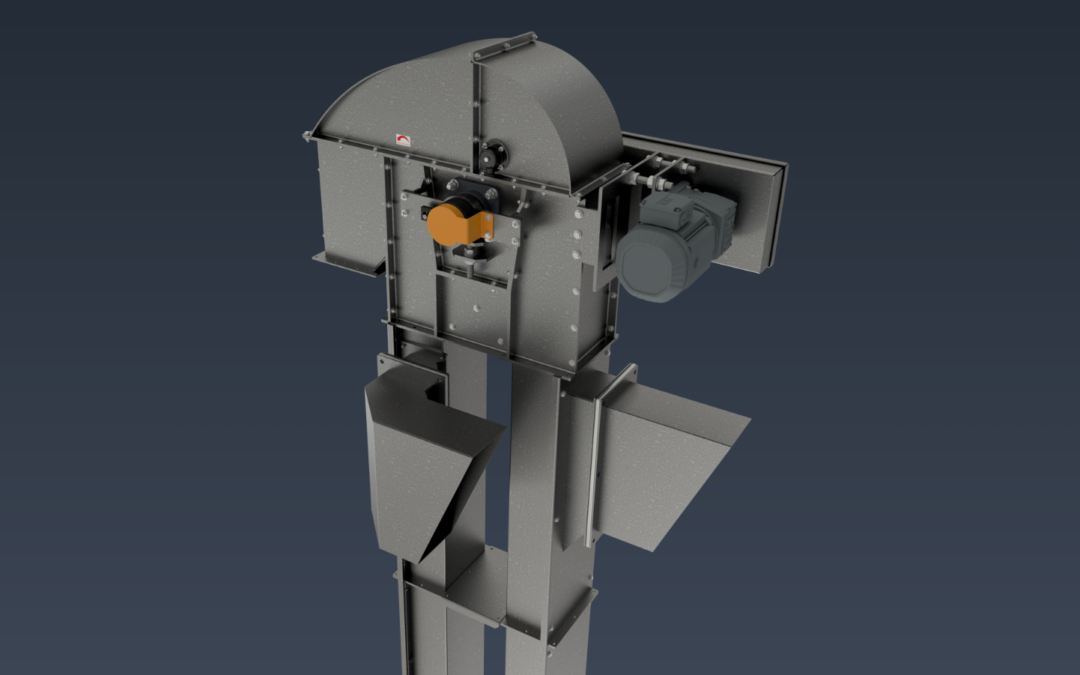

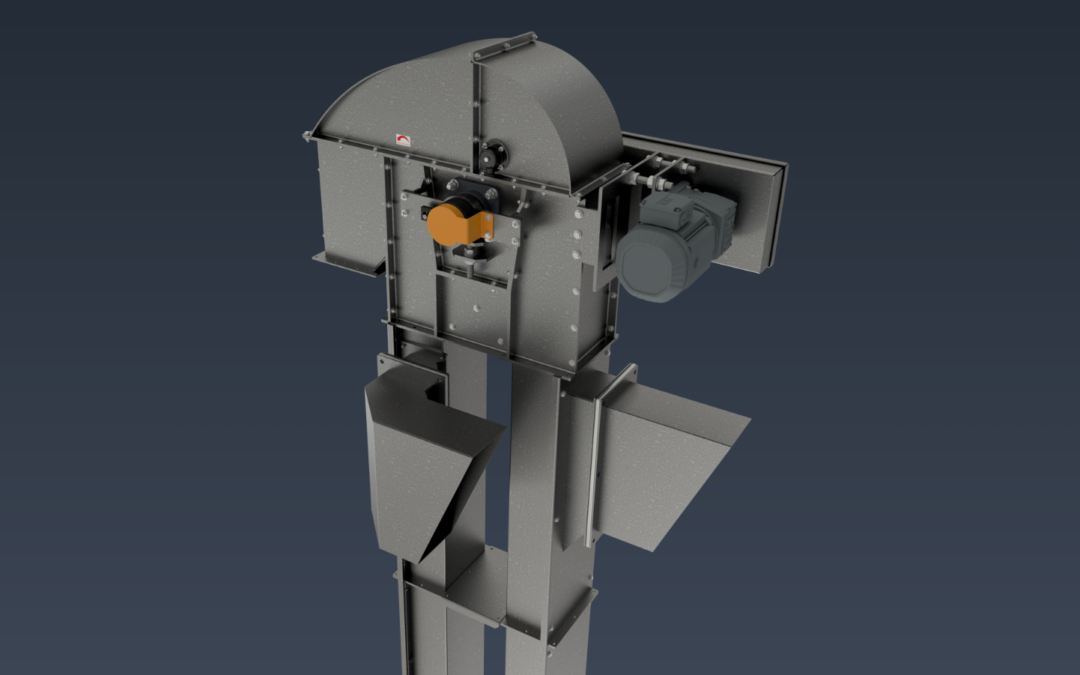

WHAT WAS THE ISSUE? Our client, a manufacturer of Aqua Feeds based in Scotland who we have worked with since 2020, had discovered that two of their belt and bucket elevators (E103 & E211) had reached the end of their usable life. Subsequently this would mean...

by Helen Fletcher | May 8, 2024 | Case Study

What was the issue? We have been working with a new Norfolk based client to upgrade their animal feed mill and enhance production of their high-quality animal feed. They came to ISF initially following a recommendation, as they needed help in upgrading their press...