We specialise in delivering cutting-edge engineering solutions for animal feed manufacturing and processing companies across the UK.

We manage and carry out maintenance, repairs and upgrades on animal feed mills to ensure the optimal performance and productivity of mechanical systems and machinery.

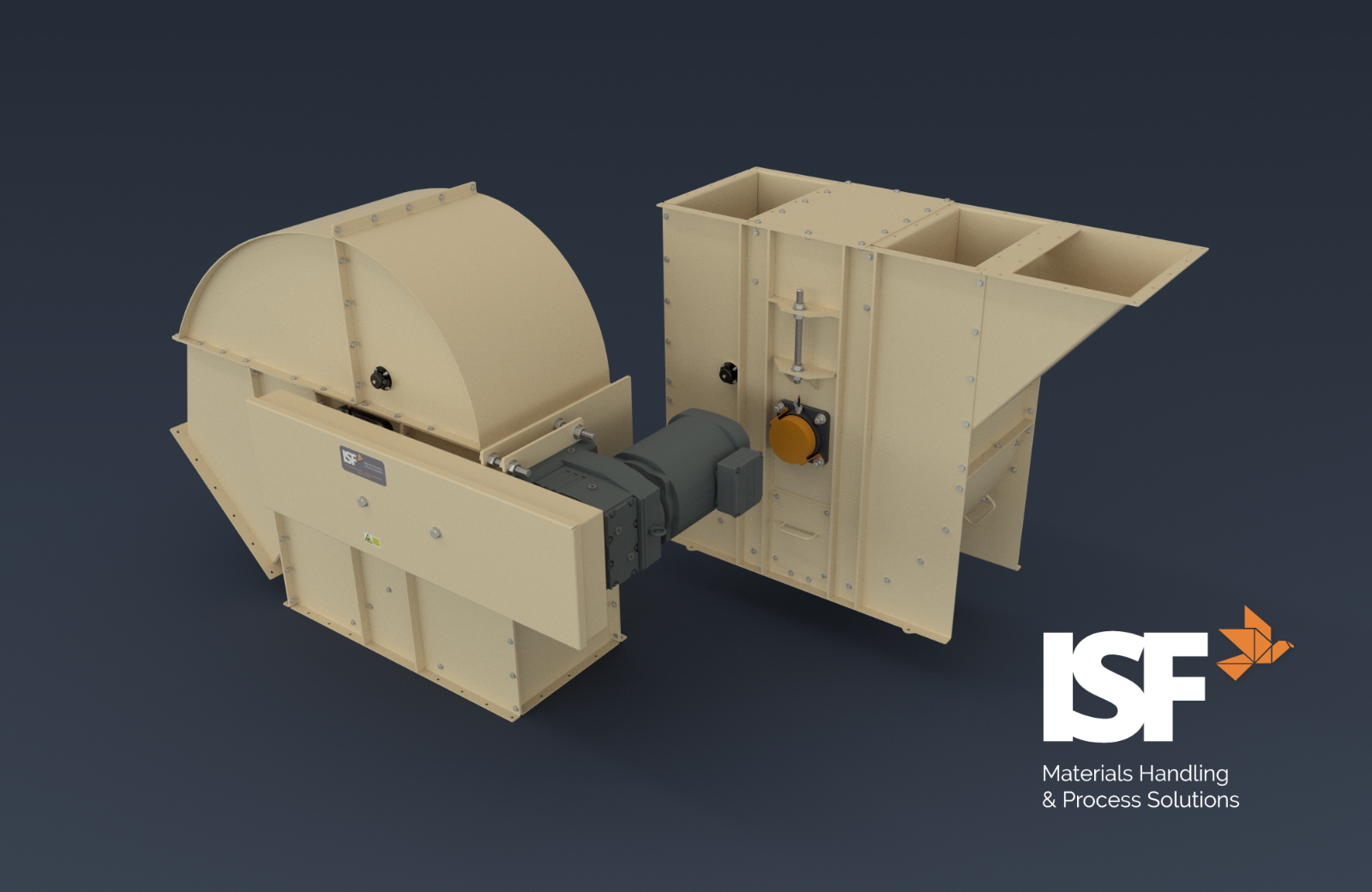

Whether you need a bespoke piece of machinery, the refurbishment of existing equipment or a turnkey project, we have the knowledge and expertise to provide and deliver the solution and offer start to finish management to make sure you get exactly what you require.

Our aim is to improve the efficiency, quality and throughput of animal feed manufacturing systems, providing seamless and worry-free solutions.

HOW WE SUPPORT OUR CLIENTS

At ISF, we provide expert engineering services tailored to the animal feed milling industry. From initial assessments and bespoke design to manufacturing, installation and consultancy, our team takes a holistic approach to delivering efficient, future-ready feed mill solutions.

This video offers a behind-the-scenes look at our process, combining decades of experience in engineering and the feed milling industry, technical knowledge and a deep understanding of client needs to improve productivity, streamline operations and build lasting value.

What is Animal Feed processing?

Animal feed is a vital part of the UK food supply chain allowing British farmers rely on British sources for their requirements. Improving efficiency, and reducing costs, are all long-term savings passed onto the consumer.

The animal feed is manufactured by combining bulk raw materials such as grain, molasses, premixes and additives, with varying physical, chemical and nutritional composition to create a consistent) blended mixture, formulated according to the specific requirements of the target animal to produce a desired nutritional response, such as growth or milk yield.

Read our latest case studies

Packing Plant Upgrade Project

Read how our long-standing Yorkshire customer can now pack multiple product lines simultaneously.

Pellet Press Upgrade for Cheshire Feed Mill

Read how our pellet press upgrade for a Cheshire feed mill increased production and improved reliability.

Mixer Upgrade in Cumbria

Discover how ISF’s mixer upgrade transformed production for a Cumbria feed mill.

Our products

Elevator Head & Boots

Diverters

Weigh Systems

Read latest news here

Our January Round-up!

January at ISF saw project milestones, new team members, industry recognition and continued investment in British engineering excellence.

Reflecting on a Remarkable Year at ISF

2025 marked a significant year for ISF. From national award shortlists to major engineering projects and continued investment in people, we reflect in this latest article.

Welcome to ISF: Meet Our New Delivery Driver, Shaun

We welcome Shaun as our new Delivery Driver. With experience in HGV driving, Shaun is settling in and helping keep projects moving safely and efficiently.