The Customer

A long-established provider of high-quality animal nutrition products in Belfast, and a valued customer of ISF since 2019.

The Challenge

Our customer had previously repurposed their old pre-grind bins and transfer route to provide additional storage capacity. However, the route relied on ageing equipment that had become increasingly difficult to maintain and no longer met modern safety and compliance standards. In particular, the floor-level conveyor posed ongoing maintenance challenges, and the existing elevator lacked sufficient explosion protection, a critical safety requirement for feed mill operations.

Our customer needed a solution that would not only bring the system up to current standards but also make day-to-day maintenance easier and safer for their staff.

Our Brief

The customer approached us to replace the existing equipment and make minor improvements to the layout that would ease maintenance access.

Our project managers began with an in-depth site survey, flying to Belfast to fully understand the requirements and constraints. ISF managed the entire process, from design through to installation and commissioning, and collaborated closely with the client and other contractors to ensure a smooth and efficient delivery and that our solution met the latest industry regulation standards.

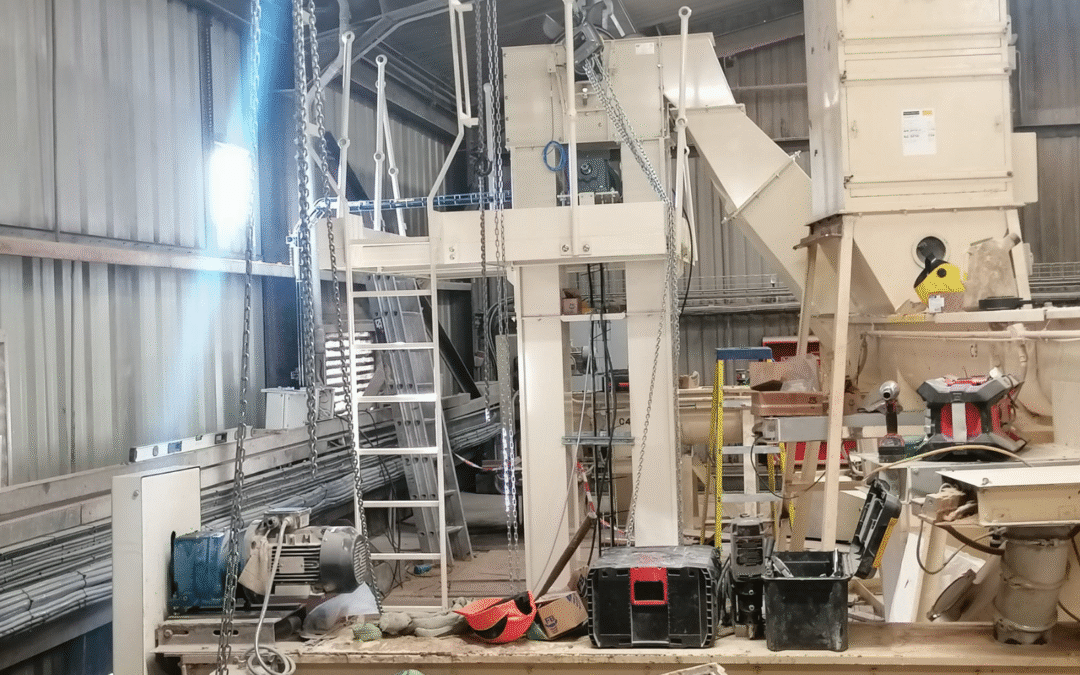

Our Solution

Following the survey, our engineering team designed a mechanical upgrade tailored to the customer’s requirements.

This included:

- Design and manufacture of electro-pneumatic slide valves

- Installation of transfer conveyors

- Supply and installation of a new belt and bucket elevator, featuring the correct explosion protection

- Addition of an improved access gantry around the elevator head to ease ongoing use and maintenance

All the upgraded components were designed and manufactured in-house by ISF to ensure full quality control and seamless integration. We coordinated the project closely with Apex Electrical, who followed our mechanical install team to handle the electrical works and commissioning.

The Result

Despite the tight schedule, the project was completed successfully within the 6-day shutdown window, including installation, electrical works, and commissioning.

The new system offers:

- Enhanced safety, thanks to compliant explosion protection on the elevator

- Improved maintenance access, reducing downtime and manual strain for site staff

- Future-ready equipment built for long-term performance and reliability

Our customer now benefits from a modernised and compliant system that supports their operations today and into the future.

Read more ISF case studies here