What was the problem?

A long-standing customer in the animal feed industry, operating a ruminant feed mill in Lancashire, approached us with a challenge. Their existing pellet press, essential for the manufacture of animal feed, had become increasingly unreliable due to age and wear. With the risk of mechanical failure becoming a problem, the existing pellet press posed a serious threat to efficient production in the mill. Given the high output demands of the mill, any unplanned downtime could have had significant financial and operational consequences.

What was the solution?

To address the issue, we worked closely with the customer to develop a plan for replacing the old press. The new press was sourced by the customer and was a significant upgrade in terms of reliability and performance. Our team was responsible for designing and manufacturing new feed and discharge chutes to suit the upgraded equipment. These components were produced in our York workshop and delivered to site ahead of the installation.

What was the process?

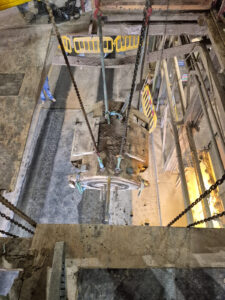

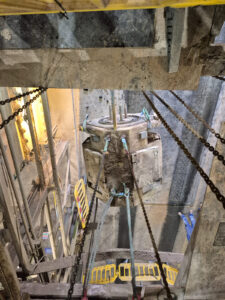

Following a detailed site survey, we agreed a planned three-day shutdown, ensuring minimal disruption to production. Once on site, the team began the installation by opening up the existing floor well, lifting floor plates and steelwork to gain access to the press location. The old, redundant press was then dismantled and removed. Given that the new press was significantly heavier than the old one, with the main gearbox alone weighing 3.8 tonnes and the total weight of the machine reaching 7.8 tonnes, it had to be disassembled into manageable sections.

Putting their lifting and slinging training to good use, our engineers carefully manoeuvred each component into the building and into position using manually operated lifting equipment including chain blocks, slings and shackles. This stage required precision and coordination, especially when guiding the heavy equipment through confined areas within the mill. Once all parts were in place, the new machine was fully assembled and installed, ready for electrical commissioning.

What was the outcome?

After the successful installation of the new press completed by our team, the plant now operates with a modern, fully functional press, greatly reducing the risk of unexpected failures. Most importantly, the throughput of the press has doubled, increasing from around 6 tonnes per hour to 12 tonnes per hour, a significant gain in production capacity. The customer was extremely satisfied with the outcome of the project and has already scheduled an identical installation at their second site near Liverpool, which is planned for completion in September.

Check out some images from the project below: