We specialise in delivering cutting-edge engineering solutions for animal feed manufacturing and processing companies across the UK.

We manage and carry out maintenance, repairs and upgrades on animal feed mills to ensure the optimal performance and productivity of mechanical systems and machinery.

Whether you need a bespoke piece of machinery, the refurbishment of existing equipment or a turnkey project, we have the knowledge and expertise to provide and deliver the solution and offer start to finish management to make sure you get exactly what you require.

Our aim is to improve the efficiency, quality and throughput of animal feed manufacturing systems, providing seamless and worry-free solutions.

HOW WE SUPPORT OUR CLIENTS

At ISF, we provide expert engineering services tailored to the animal feed milling industry. From initial assessments and bespoke design to manufacturing, installation and consultancy, our team takes a holistic approach to delivering efficient, future-ready feed mill solutions.

This video offers a behind-the-scenes look at our process, combining decades of experience in engineering and the feed milling industry, technical knowledge and a deep understanding of client needs to improve productivity, streamline operations and build lasting value.

What is Animal Feed processing?

Animal feed is a vital part of the UK food supply chain allowing British farmers rely on British sources for their requirements. Improving efficiency, and reducing costs, are all long-term savings passed onto the consumer.

The animal feed is manufactured by combining bulk raw materials such as grain, molasses, premixes and additives, with varying physical, chemical and nutritional composition to create a consistent) blended mixture, formulated according to the specific requirements of the target animal to produce a desired nutritional response, such as growth or milk yield.

Read our latest case studies

Animal Feed Equipment Upgrade in Belfast

Our solution to bring a valued customer’s system up to current standards and make day-to-day maintenance easier and safer.

Installing a pellet press replacement at a ruminant feed mill in Lancashire

How we helped a long-standing customer with a plan to replace their old pellet press.

Upgrading the press, conditioner, crumbler, and sieve as the second phase of poultry feed mill upgrade in Buckinghamshire

At the end of last year, we worked on a project with our Buckinghamshire client to improve product turnover in their...

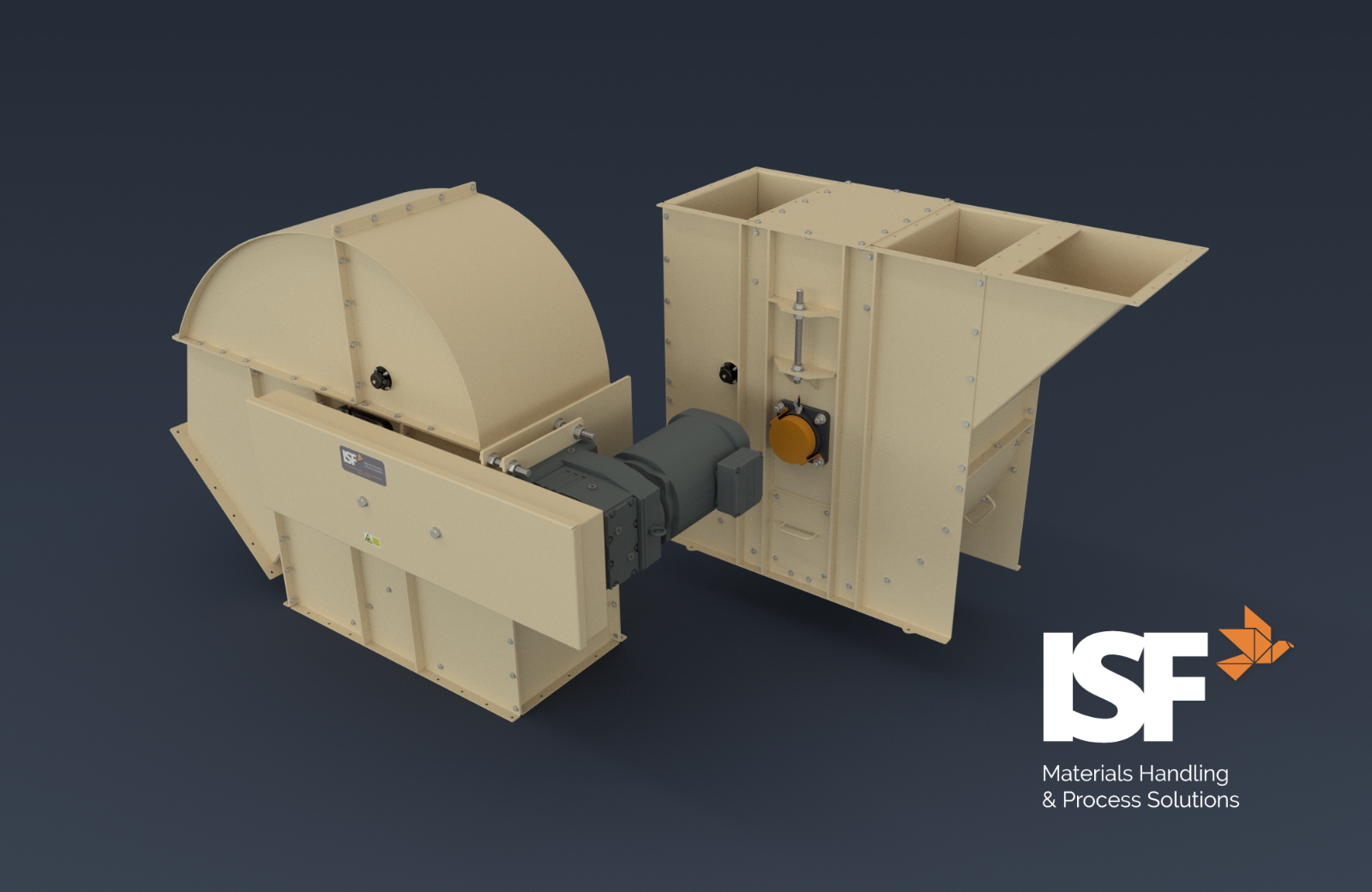

Our products

Elevator Head & Boots

Diverters

Weigh Systems

Read latest news here

An ISF Christmas Carol

An ISF Christmas Carol — a look back at our journey over the years, from our early days in York to the projects, people, and milestones that have shaped ISF.

Our November Round-up!

November was a productive month at ISF, with progress across our projects, people and customers. Here’s a look at what we’ve been up to.

Q&A with Returning Team Member, Dave Peden

Meet the former Installation Engineer who’s returned to ISF as Installation Coordinator, ready to hit the ground running.